Our Product Range

We manufacture following type of Heat Exchangers

- Wire Wound Finned Tubes

- Strip Finned Tubes

- Finned & Tube Type Heat Exchangers

- Shell and Tube Type Heat Exchangers

- Air / Steam Heaters / Driers

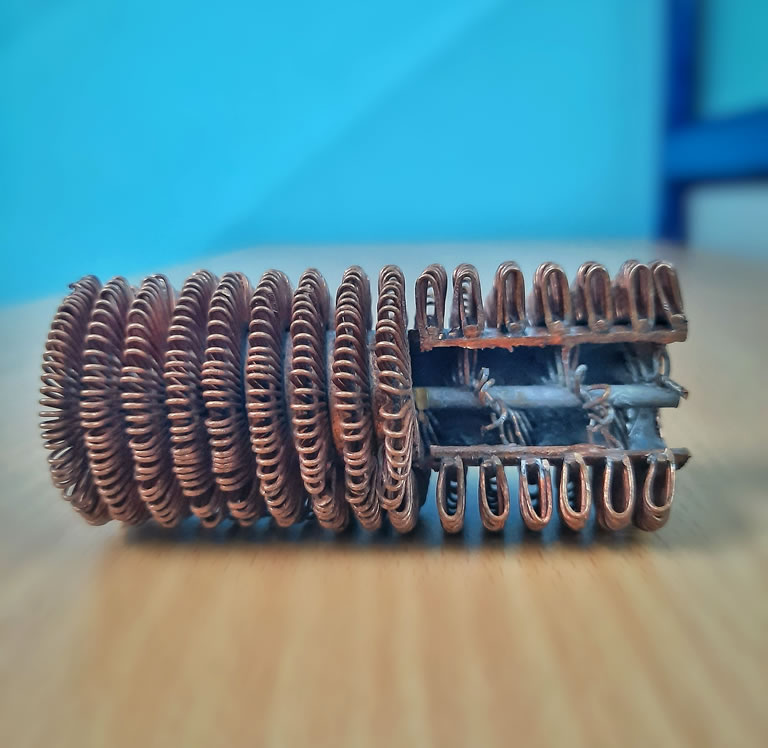

Wire Wound Finned Tubes

In this technique, continuous loops of Copper Wire are wound on the Copper tube. This wire is later soldered to the copper tube. These soldered wire finned tubes ensure very High Heat Transfer Efficiency. In this process, the efficiency of the heat exchanger is increased as per the customer's space availability. This process is done by our trained labourers since even a minor change would affect the heat exchanger's performance. We have machineries to manufacture Cu, Brass, CuNi., S.S. and GI Wire Wound Tubes that are Electroplated & Hot Dip Galvanized.

The Wire Wound Finned Tubes finds its application majorly in the manufacturing of Oil Coolers and After Coolers.

Crimped & Spirally Wound Finned Tubes

We specialize in the manufacturing of Crimped & Spirally Wound Strip Finned Tubes. Crimped and Spirally wound finning is one of the techniques to extend the external surface on the tube to increase the Surface Area. By this way, the Efficiency of the Heat Exchanger is increased. A copper strip is crimped and wounded over a copper tube. This process is done by our specially trained labourers with great precision in order to enhance the heat exchanger's performance. We have machineries to manufacture Cu, Brass, CuNi., S.S. and GI Strip Finned Tubes that are Electroplated & Hot Dip Galvanized.

We specialize in the manufacturing of crimped and spirally wound heat exchangers which finds its major applications in the manufacturing of Inter Coolers, After Coolers and Oil Coolers.

Finned Tube Heat Exchangers

There are various types of Finned Tube Heat Exchangers which are used for applications. Over the years, we have acquired extensive knowledge about Heat Exchangers and we have emerged as the pioneers in the manufacturing of Oil Coolers, Inter Coolers and After Coolers.

Oil Coolers

Oil cooler is mostly used to remove the excess heat from the engine. The hot oil leaving the engine usually passes through the oil cooler in which the temperature of the oil is reduced. We specialize in the manufacturing of oil-air heat exchangers as the air pulls out the excess heat from the oil. In finds it application in mining, bore machines etc.,

Inter / After Coolers

Both inter and after coolers are mechanical heat exchangers that is used to cool the compressed air back to near ambient temperature to increase its efficiency. We specialize in manufacturing of inter and after coolers for more than 30 years which are majorly used in railway engines.

Shell and Tube Type Heat Exchangers

This heat exchanger consists of a shell and a bundle of tubes inside either plane, longitudinal, finned etc., Shell and tube Heat Exchangers have the ability to transfer large amounts of heat in relatively low cost and has serviceable designs. They can provide large amounts of effective tube surface while minimizing the requirements of floor space, liquid volume and weight. The maintenance of shell and tube heat exchanger is very is easy and simple when compared to other technologies. It is used in various applications like cooling fluids and oils in engines etc.,

Air / Steam Heaters / Driers

Content Coming soon...

Our Specialized Products

Finned Tubes with Wire Turbulator

Generally, Wire Wound Finned Tubes consists of loops of wire that are soldered to the outer circumference of the tube to increase the Heat Transfer efficiency. But, to increase the efficiency even further, we make specialized finned tubes which contain wire Turbulator on the inside of the tubes. The wire turbulator within the tube increases the tube side heat transfer efficiency by a factor of 3-10.

Compact Coolers

As electric railway engines are replacing diesel engines, compact coolers is taking up a major role in recent times and we specialize in mass production of them. Each part of the cooler is fabricated within our premises and every process is double checked to ensure accuracy. The design team here is highly qualified and always up to date when comes to heat exchangers and its types. We have trained welders who precisely weld very intricate parts with high degree of accuracy. It finds its application in railways.